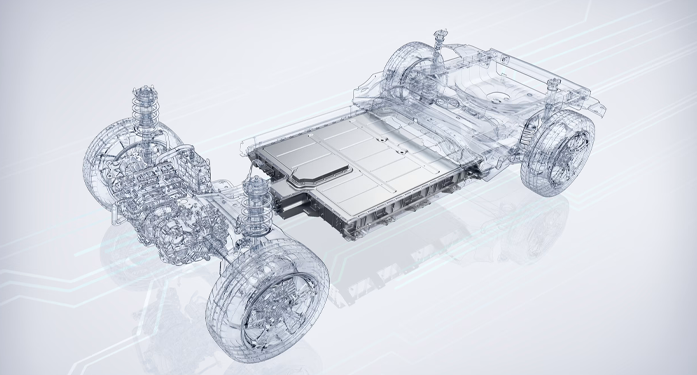

Toronto, Ontario — A pair of new products from German parts developer Continental may pack the one-two punch needed to both allow repair facilities to more accurately assess electric vehicle battery damage, while also allowing OEMs to do away with the excess body materials used to protect the battery pack.

When equipped with the Current Sensor Module (CSM) and Battery Impact Detection (BID) system from Continental, the former can detect and warn of impacts to the battery pack’s protective structure, while the latter, meant to be used in combination with a lightweight body structure, “detects underfloor impacts and alerts the driver if a stop at a garage is necessary as a result,” according to the company.

Previously, the alternative for drivers was to physically look underneath their vehicle for damage and make the determination for themselves whether or not to seek repairs.

“This is not a satisfying situation as there is poor visibility underneath a car, plus it takes a trained eye to assess the true damage,” Johannes Clemm, managing director of Continental Safety Engineering International in Alzenau, Germany, said in a statement.

“In addition, the BID identifies the area of the damage, so the battery management can empty the cells in that area to prevent any risk of fire,” said Clemm.

The company suggested that when low-speed contact occurs, the BID could tell a fast-acting suspension system to raise the vehicle, reducing the severity of the damage.

Continental also claims that with a BID system installed, a vehicle can shed up to 50 percent of the weight that would ordinarily be strictly allocated to protecting the battery pack.

The pressure sensors used in the BID were derived from Continental’s Pedestrian Protection System (PPS), which has been in series production for more than ten years and can be found in millions of vehicles. The system detects impacts via air-filled silicone tubes at the bottom of the battery compartment and can determine an impact’s location and severity.

The CSM can measure the current and detect temperature at the same time, providing information to the vehicle’s battery management system.

“Considering that the battery is the single most expensive component in an electric car, the CSM was not just developed to protect the battery from overcurrents, but it will also help to retain the battery parameters by limiting aging effects,” Continental said.

Part of the CSM’s function is to control the battery’s charging current in order to manage its temperature output.

“A lithium-ion battery has an optimum temperature span in which it is very safe and ages very slowly,” said Horst Gering, program manager in the company’s passive safety and sensorics segment.

“However, fast charging the battery is a tradeoff between keeping the battery safe and healthy and limiting the duration of charging. This is best done on an exact data basis.”

Continental said that the CSM could be integrated into a vehicle’s battery disconnect unit, or into the battery pack itself. The sensor will go into series production before the end of 2022, and will be offered in a global automaker’s EV, the company said.

“Vehicle electrification brings new use cases and thus opens up more opportunities to our sensor activities, because an electric car has all the sensor needs a conventional car has—and more,” Laurent Fabre, head of passive safety and sensorics segment at Continental, said in a statement.

“Protecting the battery and retaining its performance, for instance, are two additional tasks in electrified vehicles. The Current Sensor Module and Battery Impact Detection solutions serve both purposes.”