Automotive Recyclers of Canada share Plastics Roadmap study results

By Steve Fletcher

90 AUTO RECYCLERS SURVEYED

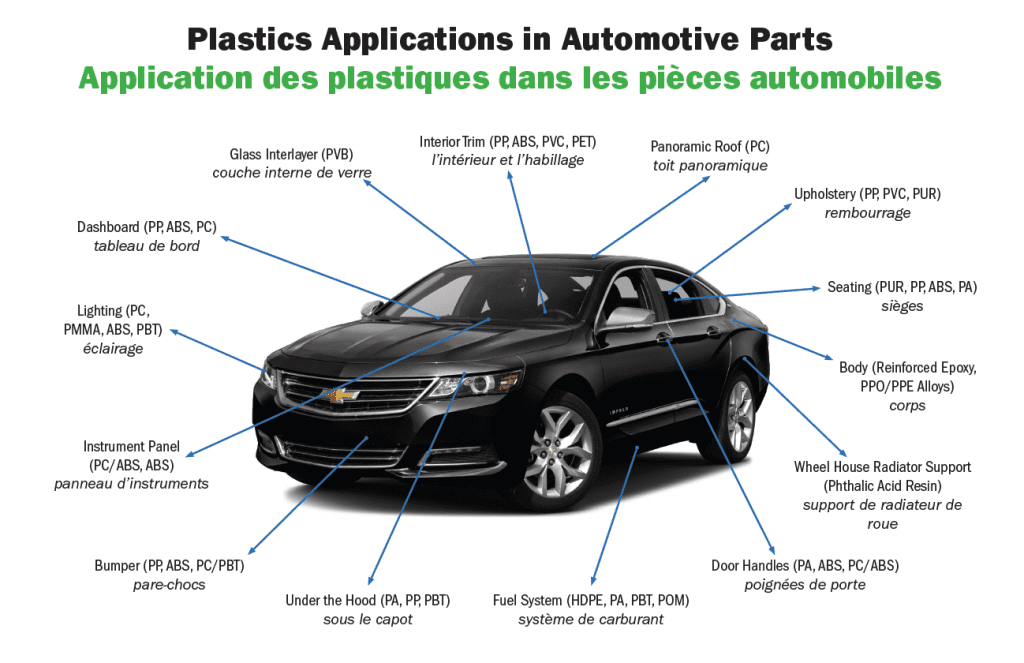

Canada has set a 2030 target in the mission to produce zero-plastic waste. It has been estimated that the auto sector produces about 476,000 tonnes of plastic waste annually, or about 17 percent of the total waste plastics generated.

About 1.6 million vehicles are retired in Canada each year and each endof- life vehicle (ELV) contains about 175 kg of various plastic resins. Recycling rates for plastics contained in ELVs are currently low because markets are not available for many of the plastics currently found in vehicles: technologies do not currently exist to recycle all the different plastic components found in vehicles; and many of the plastics are built into the vehicle itself.

The Automotive Recyclers of Canada (ARC) undertook an Auto Plastics Roadmap study, with funding from Environment Canada & Climate Change (ECCC), to identify the obstacles to increasing the recycling of pre-shredder auto plastics in Canada.

An online survey was sent out of 500 auto recyclers across Canada with over 90 responses, followed up by interviews with selected auto recyclers. Suggestions on how ECCC could facilitate an increase in auto plastic recycling included: providing bins for plastic collection at each auto recycler site; providing shredders to shred collected plastic to reduce volume before transportation; providing regional shredders; providing a bounty to recover labour and full costs for removing marketable auto plastics; creating end markets for auto plastics; creating regional processing facilities; better labelling auto plastics for easy identification of plastic resin; identifying types of plastic that are reusable/recyclable and pay per piece recovered; and providing funding to transport auto plastics to recyclers.

A teardown study on a variety of vehicles was undertaken to measure the amount of time required to extract different plastics from end-of-life vehicles as part of the normal depollution and parts harvesting process (i.e., to recover engines, transmissions and other auto parts for resale); as well as a deeper dive to see how much effort it takes to recover as much plastics as feasible. The study concluded that it was very expensive to recover auto plastics at this stage in the value chain, as the measured rate of plastics removal was 28 kg/hour. At this rate, it would take approximately 34 hours to remove 1 tonne of auto plastic from ELVs at an estimated cost of $3,400/tonne. While this is not considered a realistic or economically viable approach, a few specific actions hold promise.

The ARC Roadmap recommended a three-year research program potentially diverting over 83,000 tonnes of auto plastics from landfill with a total estimated budget of around $6,340,000 over three years (2022 through 2024).

Three recommendations were deemed noteworthy as potentially cost-effective:

Collision Repair Sector Research

The roadmap identified that the collision repair sector could potentially be a promising location where auto plastics could be recovered for recycling. A research project is proposed to quantify the potential opportunity.

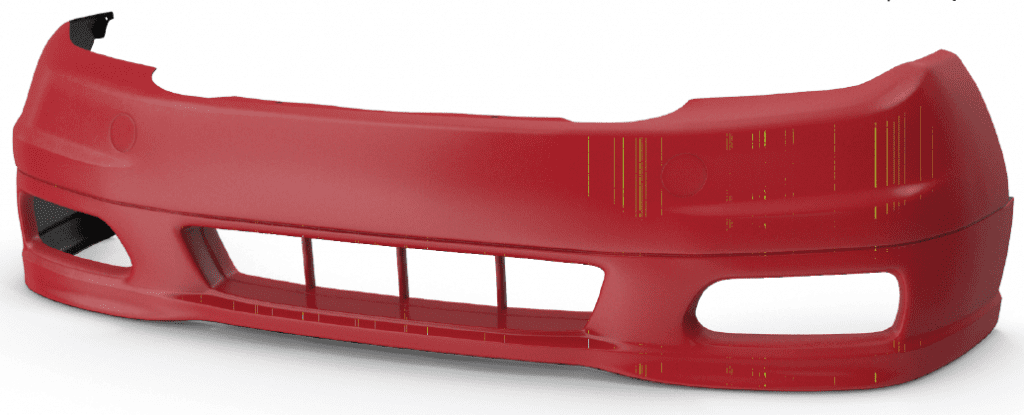

Bumper Recycling Enhancement

Research showed that bumpers are made of TPO which is a recyclable plastic resin. Some bumper recycling activity is already underway in Canada. Bumpers are easily removed from most but not all EOL vehicles, therefore minimal labour cost is involved. The proposed enhancement program would provide a bounty to auto recyclers and potentially collision repair locations to encourage auto recyclers to remove and store bumpers separately for collection and recycling.

Gas Tank Recycling

Most gas tanks in Canada are made of a combination of plastics. Gas tanks are a good target to increase the recycling of auto plastics as they are often removed from vehicles already for depollution. The challenge is that technologies are not yet available to recycle the combination of plastic materials used in gas tanks, which also contain some gasoline residues. This research project would support technology development to explore and establish end markets for gas tanks, eventually leading to a gas tank recycling program.

The report also noted that the recovery of auto plastics from ASR (auto shredder residue) is in the early stages of development and when technically viable would also offer a promising route for Canada to recover auto plastics. At this time ECCC is evaluating the report to determine which, if any, of the recommendations can be pursued and funded. They have also initiated a project to develop a federal plastics registry for producers of plastic products, including plastics in vehicles.

Further information on the Roadmap to Increase Recycling of Auto Plastics from End-of-Life Vehicles in Canada can be found at autorecyclers.ca/about-arc/plastics-from-elvs-study.

Pensez aux procédures OEM qui prévoient le remplacement des pare-chocs pour chaque bosse et éraflure.