Cousin—owner duo Natalie and Chris Miller on operating the family ’biz, Miller’s Auto Recycling

By/Par Sarah Perkins

The automotive recycling industry has always been one to build on the foundations of the past to create something new. From repurposing materials previously manufactured to bringing new lives to old parts, automotive recycling is about finding a fresh focus in familiar places.

However, for cousins Natalie and Chris Miller of Miller’s Auto Recycling, the automotive recycling industry is not just familiar, but familial.

The third generation in a family business that first began nearly 75 years ago, Natalie and Chris spoke with Canadian Auto Recyclers to discuss how a blend of homegrown knowledge passed down from branch-to-branch of their family tree, mixed with modern technology and business practices, has created continued and ongoing growth while also preparing them for continued future changes.

The family business that would become Miller’s Auto Recycling—now a large-scale operation on a sprawling 45 acres in Fort Erie, Ontario—first began on a humble two-acre lot on Robinson Street in downtown Fort Erie in 1952.

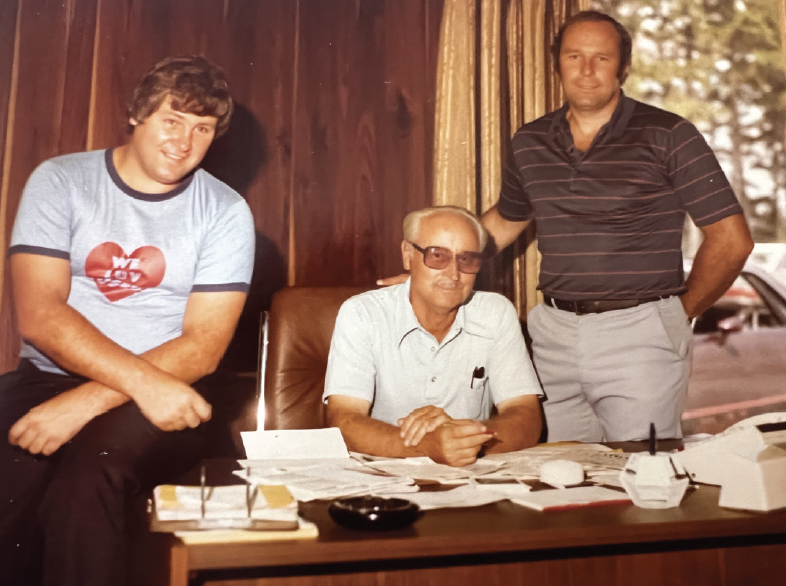

Here, Chris proudly noted that he and Natalie’s grandfather opened the original business purchasing end of life vehicles for the resale of used parts at the Robinson Street location. A move that would ultimately shape the lives of the next two generations of Miller kin.

Both Natalie and Chris’s fathers, Jim and Bill Miller grew up working on the vehicles on the Robinson Street lot and eventually came to purchase the business from their father as co-owners with the intention to help grow and expand both the size and scope of what had been started. This growth included purchasing land and building a new facility in 1975 at 1557 Bowen Road where the business operates today.

Like their own fathers, Natalie and Chris similarly spent a childhood that was equal parts lived in the schoolyard as much as the family business. When asked about their early years in the automotive recycling industry, Chris jokingly told Canadian Auto Recyclers that his career began with a bang. “I first started helping out by cutting copper as a kid and helping to get the rubber off,” Chris said. “The process back then was a little different and best practices for safety were not in place as they are today.”

As he grew older, Chris transitioned from copper-cutting-capers to helping with more hands-on jobs. He worked summers until he was done with high school, attended night courses at college and worked during the day, and then came into the business full time in 1988.

For Chris, there was “not necessarily a plan to get into the family business,” but the transition was natural and welcomed. As he began to help his father out with more and more tasks, he grew into the role and accepted that he was “hooked from day one.”

“It’s a good place to be,” Chris told Canadian Auto Recyclers. “It’s close to home and I feel fortunate to work in the community I live in.”

For Natalie, the path to the automotive recycling industry was initially less straightforward. Performing some administrative work over the summer for the family business while attending university, Natalie then pursued a career as a physician’s assistant specializing in Orthopaedic Surgery in the United States. It wasn’t until 2009 that Natalie returned to work at Miller’s full time, taking on the role of managing human resources.

Having just had her daughter, Natalie saw the return as an opportunity to achieve more freedom for herself and her family.

“I liked the idea of having more flexibility and loved the idea of the business,” she said. It wasn’t until 2015 that the cousins finally fully followed in the path originally laid out by their fathers and grandfather, and bought into the family business with the intention of growing Miller’s Auto Recycling even further. Since then, Chris and Natalie, who oversee the daily operations, along with Jim and his son Patrick, have helped lead Miller’s through a series of transitions—both planned and unforeseen.

While at one point, Miller’s aimed to be a “one stop shop” for the recycling and collision industry by featuring a collision centre and a mechanic shop alongside the existing dismantling and parts service, Chris and Natalie saw that the business needed to “downsize to upsize” in order to keep up with the rapidly increasing demand for quality recycled parts. As a result, the collision shop was quickly turned into a dismantling facility and the Millers further committed to the auto recycling industry.

The family business also transitioned to working on more late model parts vehicles rather than predominantly focusing on end-of-life vehicles. The parts cars are processed to the same environmentally friendly standard that Miller’s holds itself to, and offers a greater economic incentive. Here, Chris discussed how the past few years have seen the business grow not just in size and practice, but also technologically. “Changes in technology have allowed the industry to drastically shift. It’s changed the buying process especially. Now, instead of going to auctions or car lots, you never have to leave. You can do everything from your desk.”

He recalled how when his father first saw him working on a computer, he said “what are you doing? Let’s go do some real work.”

“It was intimidating to begin in the industry, even though I grew up in it,” said Natalie. “But, I quickly learned that it’s a close community and we can always talk and learn from one another no matter the size of the business. So, it wasn’t long before I felt comfortable in the industry”

— Natalie Miller, co-owner, Miller’s Auto Recycling

For Natalie and Chris, real work is in keeping with the times and continuing to plan for whatever changes and challenges the industry may bring, whether this be intricate software systems or cultural highs and lows.

“Everyday is a new adventure,” the cousins noted. “There’s always a learning curve and it’s a kind of learning that you can’t necessarily get in school. It’s something you have to get from within the industry itself.” But, as Chris and Natalie further discussed, for members within the automotive recycling industry, repurposing is the name of the game even when it comes to information, and so someone is always willing to help with a challenge or provide data.

“It was intimidating to begin in the industry, even though I grew up in it,” said Natalie. “But, I quickly learned that it’s a close community and we can always talk and learn from one another no matter the size of the business. So, it wasn’t long before I felt comfortable in the industry.” This community mindset became especially vital during the pandemic in which Miller’s Automotive Recycling gained opportunities to network and grow into the United States and leaned on the support of the industry to help develop increased connections. When asked by Canadian Auto Recyclers what the future holds for Miller’s Automotive Recycling, Natalie and Chris were unanimous in their answer: growth.

“We’re continuing to work on developing a strong team,” said Natalie. “Covid has presented challenges in the industry in hiring and retaining staff, but ultimately, we are working on continuing to create a culture and environment that is purposeful and shows current and potential employees the value of the industry.”

Moreover, just as the family business has been passed down from branch to branch of the Miller family tree, so too would Chris and Natalie like to see it continue to the fourth generation.

“The hope is that we can keep the business in the family,” Chris said. When asked what advice they have for those in the industry, the cousins had this to say: “a successful business doesn’t grow overnight. It’s about learning to be efficient, develop a process and optimize it, and this can be done just as well on five acres as 50 acres.”