Toronto, Ontario — Automotive recyclers everywhere are wondering how they may sell electric vehicle (EV) parts as the zero-emissions vehicle parc grows–but they should fear not, as there are huge opportunities for recyclers willing to gain knowledge and take on the electric challenge.

That’s the sentiment EV consultant David Giles left the audience with last weekend at the Ontario Automotive Recyclers Association (OARA) Convention and Trade Show when he delivered a compelling discussion on electric vehicles and profitability for recyclers.

Electric adoption

Giles began his presentation by noting that EV adoption numbers across Canada are rising, with Tesla claiming the largest market share.

“There is evidence that EVs, particularly Teslas, will eventually begin to populate Canadian roads and repair facilities—eventually leading to recyclers,” he said.

Giles told the audience that he has personally dismantled and rebuilt at least 60 EVs.

“When I started AllEV Canada, our goal was to take damaged, smashed EVs that could be returned to the road, rebuild them and make them more affordable to people.

“Then we discovered people didn’t want to buy rebuilt electric vehicles.”

Giles explained that, while the company continued to purchase salvage titles, AllEV Canada took many of its cars and repurposed them for training.

“We turned it more into a public training to show automotive industries how to work on EVs.”

Types of batteries

Giles pointed out that there are many different types of lithium-ion batteries present in modern EVs and, as a recycler, it is crucial to know the difference.

“A nickel-cobalt aluminum (NCA) battery is worth much more than an LFP battery, due to nickel content. Nickel is worth a lot of money, compared to lithium—an LFP battery has no nickel.”

He also noted that kilowatt-hours are another critical KPI.

“You may have a lithium-ion battery in a vehicle with 100kwH worth, let’s say, 10,000 dollars, in a reused purpose. Then you may have another battery with 8kwH—which is worth much less.

“If that battery is a sodium battery, it’s worth even less.”

Learning curves with EV dismantling

Some big learning curves come with EVs, especially for the staff touching them. Top-of-mind for many is the high-voltage battery and the general safety implications of working around it.

That’s reason number one why understanding connections and depowering batteries safety is of paramount importance.

“Every vehicle is different in how it de-powers itself. The energy still exists within the vehicle, even if it has been de-powered.”

“High voltage does kill—it doesn’t have a feel, other than a zap. But you’d already be gone.”

The solution to this—training, said Giles.

“If you have a team that understands EVs and how to work with them, with proper training—there is no risk to them.”

Without training, though, “you are sitting on a ticking time bomb.”

Another learning curve with EVs is often kept at the back of the mind—the terminology.

“Again, being educated is key. Knowing how ‘state of charge’ is different than ‘state of health.’”

Giles noted there are probably more than 10 pages of terminology the average automotive worker could learn about EVs.

EVs have fewer parts...does this mean less money?!

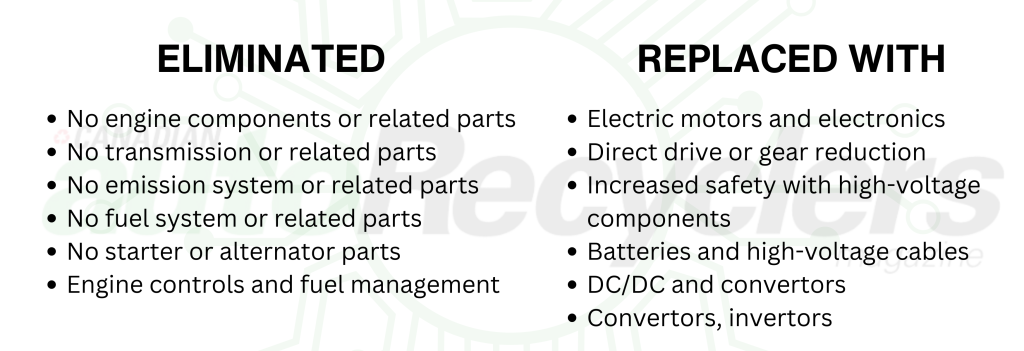

A common myth noted by Giles—that EVs have fewer moving parts, so there must be less money in them, where recyclers are concerned.

“‘There are fewer parts in EVs! There’s no money there! Fewer moving parts mean less wear and tear!’” he said, sharing opinions he’s heard in his industry travels.

“That’s actually incorrect. All we’ve done with electrification is changed things. Our ICE engines are gone—but we’ve replaced them with essentially an electric drive unit. Parts still exist—they’re just different kinds of parts.”

Recyclers should not write off these components as worthless.

“These are all replaceable. They do wear out, they do fail,” said Giles.

One of the most frequently asked questions Giles receives—what are some of the most valued items on an EV?

“I like to rephrase that. There is no sum on these vehicles—every part has value. The parts that have value will be valuable to different people in the industry, whether it’s a collision shop, an educational trainer—all EV parts have value.”

Then there’s the “good, the bad and the ugly.” The good, said Giles, is that EV parts generally present higher values, as they are sold as premium vehicles.

The bad—not being properly trained on how to handle them and potentially damaging a valuable part in the transporting process. The ugly results when you do encounter damage on a high-value part, possibly rendering an EV purchase significantly less valuable as a recycler.

Giles then noted the current trend that sees OEMs restrict certain parts, essentially barring anyone but certified entities the ability to sell particular parts.

“In the recycling world—a part that you now cannot buy from an OEM dealer, you have sitting on your shelf.”

Sometimes that can be something as simple as a clip, he added.

He then used Tesla as an example, which restricts its parts to certified authorities.

“Sometimes someone won’t be able to buy that one part needed to make an EV run,” said Giles before holding up a Tesla fuse. “This fuse from Tesla is $27 dollars. Because it’s restricted, it’s sold for up to $300 on eBay or the aftermarket.”

Another question that’s top-of-mind for recyclers—how much are batteries worth?

“It’s true, the battery has a lot of value—but it is critical to know the state of health of the battery, the condition of the battery and the battery size and type.”

The state of health, he said, will determine the next step in the battery’s life cycle. Whether it will be recycled to black mass, for example, repurposed or otherwise.

He noted that sometimes VIN codes do not deliver that information automatically and you must go searching for it in the vehicle software. This process could also require additional tools and connectors.

The biggest investment

The biggest investment that will come along with EV adoption is training, said Giles.

“You have most of the requirements for tooling, aside from safety items. But you need training and access to information.

“Training, proper equipment and safety information. These three things will make you successful in processing, removing parts from the vehicles and preparing them for resale.”

He noted that business owners should not be afraid of how much it may cost to implement and electric vehicle adoption strategy, and instead look at understanding how to meaningful adopt them into your workflow, from training to shop layout for ultimate success.

Giles ended his presentation by showing the crowd the EV Emergency Response app, which provides access to jack point locations, cable locations and plenty of other important information for anyone handling EVs. Click here to download the app.