The North American auto recycling advantage

By/Article de Steve Fletcher

Hollander Interchange has revolutionized the North American auto recycling market for more than 85 years. But most people outside of the auto recycling industry have never heard of the term interchange. I turned to ChatGPT for an AI definition: “In the context of automotive recycling, the term interchange refers to the ability to use interchangeable parts from different vehicles. The interchange system helps identify which parts from one vehicle model are compatible and can be used in another model or year. Overall, the automotive recycling interchange system plays a crucial role in maximizing the value of end-of-life vehicles by identifying and making available parts that can be reused in other vehicles, extending the lifespan of components and reducing the demand for new manufacturing.” Not bad.

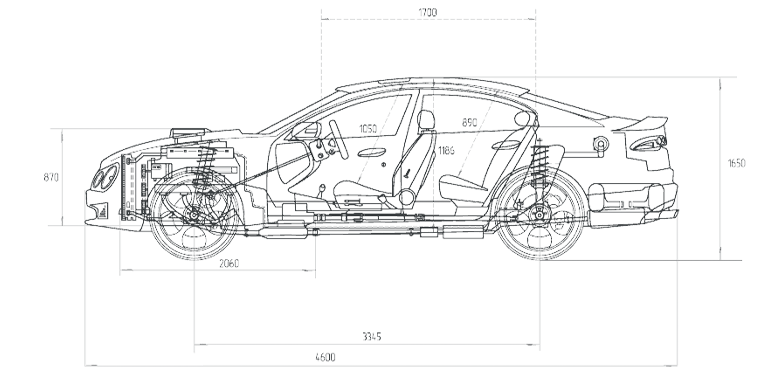

For North American auto recyclers, it is known as “Unlocking the value of Salvaged Vehicles.” And it is a unique resource to North America. Interchange allows auto recyclers, and the myriad of electronic systems they rely upon, to digitally understand what parts fit which vehicles. As an example, the 2020 Ford F150 has 462 variations considering year, make, model, trim level, body and bed style, engine, transmission, etc. And many of those parts fit year over year or between different makes and model. Interchange helps to begin to simplify those combinations.

Here are some numbers I gleaned from the Hollander Interchange from 2020: 1,221 models are covered, with an average of 155 parts and part assemblies per vehicle. There are approximately 694,000 Interchange numbers which equates to 1,804,256 part fitment applications. Over 623,000 OEM part numbers are mapped to Interchange, with 700,000 vehicles covered in the database, which represents 95 percent of vehicles in North America. Not only is Interchange used to facilitate commerce between auto recyclers but it has been remarkably successful in encouraging business with other industries. The Interchange data is licenced to all the major North American inventory management systems, part locators, auction bidding tools, core buyers – a whole host of sectors that are part of the auto dismantling ecosystem.

Wally Dingman, past Chairman of the Automotive Recyclers of Canada (ARC), sums up the state of interchange. “Accurate information is vitally important to ensure each and every sale we make goes off without an issue, meaning the part sold fits the application. However, a growing issue in the used auto parts business is lack of good information (incomplete or wrong). Wrong happens less often, but the growing issue is the incomplete information.”

Efforts are underway to improve this data collection. Hollander is investing more resources to dig deeper in to interchange. Car-Part.com is developing its own interchange on more and more part types. And the Automotive Recyclers Association (ARA) has formed an Interchange Committee to collect peer-to-peer information, notes, anomalies, and options from front line dismantling and sales staff.

This is an all-industry effort to keep Interchange alive and moving into the future. As the common language among North American auto recyclers and its partners, it is a valuable tool that needs continual enhancement and attention.

In the context of automotive recycling, the term interchange refers to the ability to use interchangeable parts from different vehicles. The interchange system helps identify which parts from one vehicle model are compatible and can be used in another model or year. Overall, the automotive recycling interchange system plays a crucial role in maximizing the value of end-of-life vehicles.

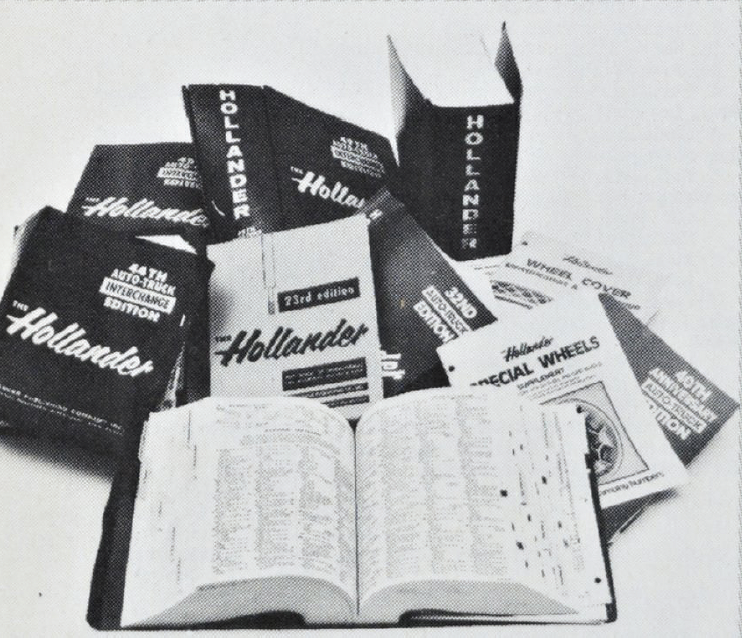

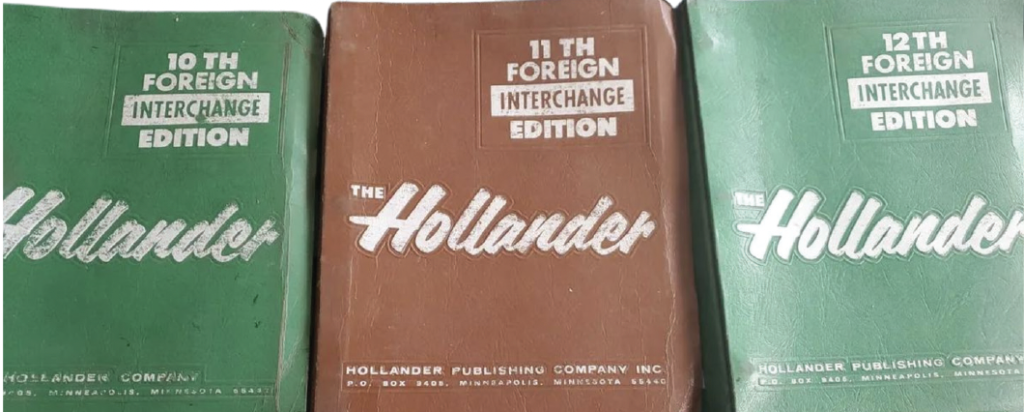

THE HISTORY OF HOLLANDER INTERCHANGE

Roy Hollander developed the idea of interchangeable parts while working as a car salesman at the start of the Depression. He’d offered a customer $75 in trade credit for a 1919 Diamond Truck that had little more than an engine, gears and wheels. After several unsuccessful attempts to sell the relic, Hollander approached an auto wrecker with the hope of recouping a portion of his investment. The man handed him $100 for the remains, explaining that the salvageable components would be sold for reuse on other vehicles at a handsome profit.

A few years later, with their music careers still on hold and jobs scarce, Hollander and his wife began a year-long study on which parts from which vehicles were interchangeable. Their plan was to sell their findings to “auto wreckers, mechanics, garages and anyone else who was interested” in the reuse of auto parts. Their concept of “recycling” used auto parts was decades ahead of their time.

Information proved difficult to access. Automobile manufacturers were reluctant to admit that some of their parts would work equally well in other models. Hollander persisted, and in 1934, published the first edition of the Hollander Interchange Manual.

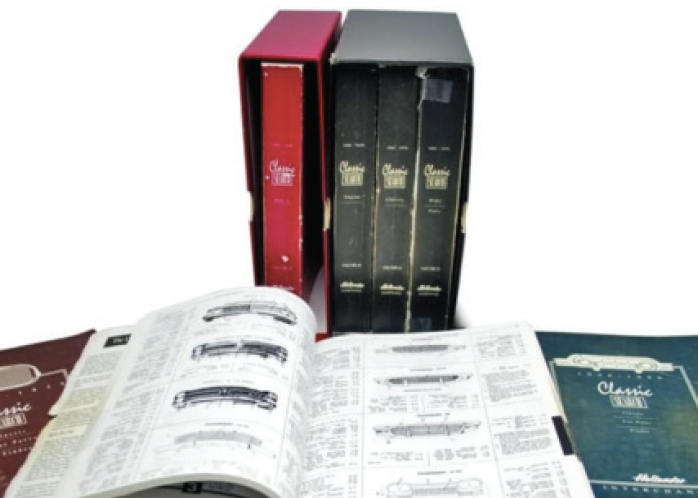

Hollander Interchange Manuals have been a staple of auto recycling operations for more than 85 years. In recent years, they’ve also become a trusted reference among individual car enthusiasts, particularly classic car collectors, restorers and parts suppliers. They are considered the world’s most complete and accurate index on auto parts for classic or restored automobiles.