Toronto, Ontario — A leading Japanese plastic manufacturer is altering the way some end-of-life vehicles are recycled.

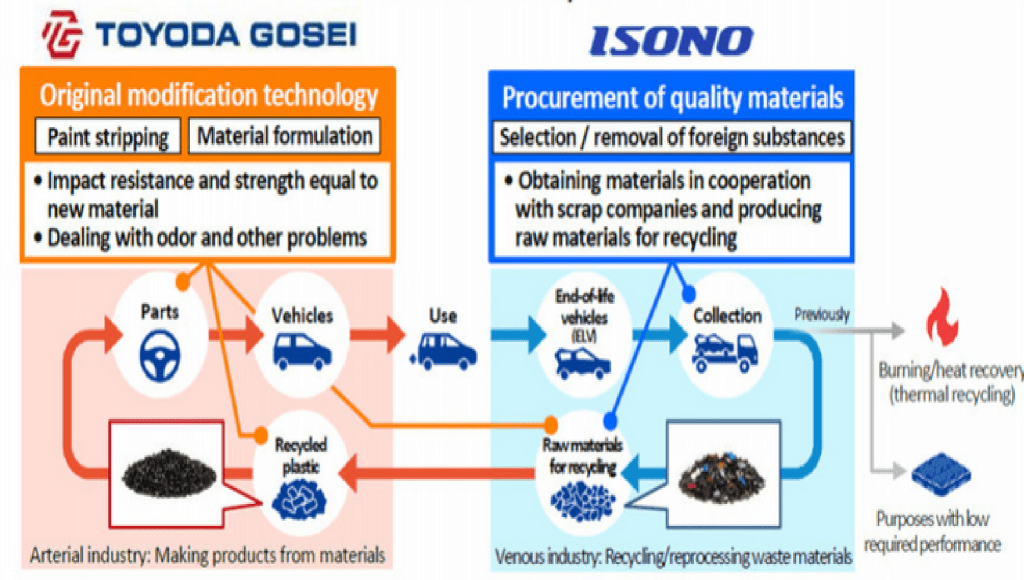

Toyoda Gosei has introduced a new recycling technology that transforms plastic from ELVs into a high-quality material suitable for new automotive parts. After processing plastics, the material is reprocessed by Isono and sold back to OEMs for reuse.

This approach, which is referred to as horizontal recycling, is meant to allow for the reuse of recycled plastic in the same type of components without compromising performance. The company uses its proprietary material modification techniques to ensure recycled plastic meet safety standards.

According to the company, horizontal recycling allows for interior automotive parts to incorporate up 50 percent recycled ELV plastic. Toyoda Gosei says its adoption of the approach could reduce its carbon footprint by 40 percent in the auto parts manufacturing sector. Some OEMs are already using recycled materials, including Toyota.