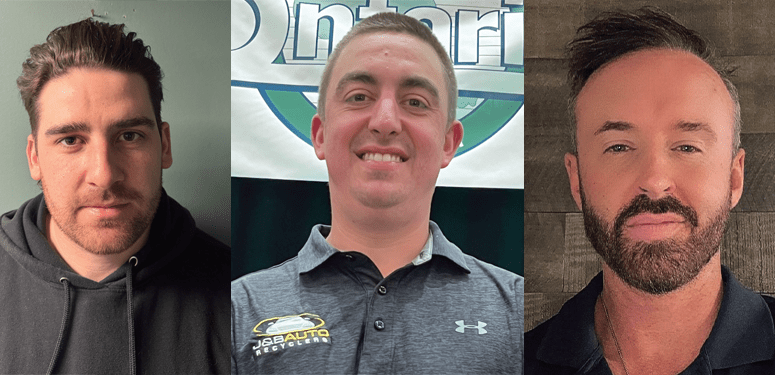

Tom Charlton, Pro Auto Recyclers. Max Winkler, J&B Auto Recyclers. Adam Budden, Auto Parts Network

Steve Fletcher sits down with young recyclers Adam Budden, Tom Charlton and Max Winkler

Story by/par Steve Fletcher

In my 33-plus years in the auto recycling industry, I am thrilled by the younger generations coming into the industry and showing incredible leadership, initiative and a bright future for the sector.

I had the opportunity sit down individually with three of those Young Leaders: Tom Charlton from Pro Auto Recyclers in British Columbia and Alberta; Adam Budden from Auto Parts Network in Newfoundland; and Max Winkler from J&B Auto Recyclers in Ontario. Here is our conversation.

Steve Fletcher: Can you provide a brief overview of your business?

Tom Charlton: Pro Auto Recyclers has two locations in B.C. (Abbotsford and Surrey) and we just bought Allen & Sons in Calgary. We’re just in the process of converting that to Pro Auto Recyclers Calgary. We process between 200 and 220 vehicles per month between our two B.C. locations with an average year of 2016. We have about 70 total employees, with most in B.C. right now. It’s very interesting owning multiple stores now in multiple provinces. We’re about 98 percent wholesale, two percent retail.

Max Winkler: J&B Auto Recyclers is in Windsor, Ontario, and employs 12 staff members, not including my dad and me. Family-owned since 1975, J&B began when my dad purchased the business at 21. Our main storefront spans 1.5 acres in the heart of Windsor, and we are opening a second storefront and storage facility in the city. We also operate a 10- acre holding yard just outside the city for storing dismantled vehicles.

We purchase around 500 to 600 vehicles annually, with half processed as scrap and the other half inventoried for parts. As a full-service facility, we inventory, dismantle, and sell parts directly to customers. Being centrally located, we serve many walk-in retail clients and numerous body and mechanical shops in Windsor and surrounding areas.

“I see more consolidation in this industry. Fewer and fewer members are adapting to the future, and some of the new entrants don’t take the time to understand how the business works.”

— Tom Charlton, Pro Auto Recyclers

“We still face the outdated stigma of the ‘junkyard.’ At J&B Auto Recyclers, we take pride in treating every customer with kindness and respect, making sure their experience is positive.”

— Max Winkler, J&B Auto Recyclers

Adam Budden: Auto Parts Network opened in 1996 in St Johns, Newfoundland. We have a hybrid location with full and self-service sections on 13 acres. We have about 30 employees. Aside from our core business of auto recycling, we have a major rebuilder department and a significant new/ aftermarket component to our business. Combined operations we process nearly 2,000 cars a year. Full service is around 75 percent wholesale and 25 percent retail mix. We deal with lots of drivetrains but a large component of our business is in collision because of our new/aftermarket offerings.

SF: Can you elaborate on how you got involved in the industry?

MW: My father bought J&B Auto in 1975, and I’ve been spending time there for as long as I can remember. I started with the typical jobs of sweeping, busting tires and cleaning up the yard. Over the years, I held various jobs during high school and university, even exploring a few different career paths before eventually returning to the family business. Now, after 13 years at J&B, I’m proud to be running the company and grateful to be part of such an amazing business and industry.

AB: I applied for a job with Auto Parts Network in 2003 for my second of three required work term placements for my Bachelor of Commerce. Growing up in a family-owned logging and heavy equipment business, I developed a strong interest in mechanical work and enjoyed tinkering with vehicles. This work term appealed to me as it combined my hobbies with a chance to experience a business environment. I connected well with the owner, Glenn Hickey, and returned for my third work term before being offered a business development position with APN after completing my degree.

I’ve been with the company for nearly 22 years and have been leading the organization for the past 10 to 12 years in Glenn’s absence. He took me under his wing, involving me in industry trade shows, educational seminars, and, most importantly, performance groups. Glenn has been an incredible mentor, enabling me to pursue opportunities I never thought possible.

TC: I grew up in the auto recycling industry working part-time at Pro. My dad, Don Charlton, was a very influential recycler in B.C. and across Canada. He is a mentor of mine and very progressive throughout all his years of growing the business, serving with B-CAR as President. I wanted to follow in his footsteps and take what he built and see where we could go with it.

I started full time in 2010 and start from the bottom and worked through every single facet of the business for multiple years. It felt like a prison sentence for some of the jobs, but learning the process of parts pulling, dismantling, inventory then sales, then manager of one store, then general manager, and now running the whole company. Looking back, I appreciate it. But I hated a lot of it. More, so that I was just stuck in one position for so long. I wanted to keep moving, but I had to master the position. Today, I’ll fill in the gap whenever needed.

SF: What are the primary challenges currently facing the automotive recycling industry?

AB: Acquisition and the cost of proper insurance for auto recyclers. In the past five or six years, insurance coverage costs have grown five times more expensive. As much as we can uniquely adopt or improve better practices that mitigate or eliminate risks, we are still heavily rated based on the entire industry.

Poorly run operations affect our risk rating as an industry. Additionally, major incidence, such as a fire, has a rippling affect across the entire country in terms of risk assessment by insurers. There are significant differences in how different recyclers manage risk and I feel that the impact that better practices have on differentiating one company from the next does not play enough of a factor in the eyes of the underwriter. We are in constant communication with our insurer and have had risk assessment evaluators on site to help us identify, document, train for and adopt better practices to help mitigate risk. Not just for the sake of better insurance rates, but ultimately because we simply do not want to have any significant incidents.

TC: The obvious challenge is the rise in electric vehicles. With what limited knowledge out there we have you learn slowly about the safety protocols first. We have the training center here that we send them to the course for the EVs where they learn the safe processes of how to dismantle them. We have the specialty gloves, placards, shipping.

Another challenge is attracting new people to the industry. It’s rare that someone grows up wanting to make a career out of auto wrecking. We have 14 sales members between our three locations. They have been able to make it a career and been able to support a family. We’ve been able to attract, train and get younger members.

MW: We still face the outdated stigma of the “junkyard.” The old days of gruff salespeople and unwelcoming environments are long gone. At J&B Auto Recyclers, we take pride in treating every customer with kindness and respect, making sure their experience is positive.

This challenge also brings an opportunity for us to educate people about the value of choosing auto recyclers. We’re proud to offer high quality, inventoried parts in a clean and professional environment. Whether you’re an individual customer, a bodyshop or a repair shop, you can always count on us for reliable service and sustainable solutions. For us, J&B Auto Recyclers is more than just a business, it is part of the community.

We’re here to show that we’re not a “junkyard” but a modern, environmentally conscious facility that cares about doing things the right way. Together, we can show the world that sustainability and quality can go hand in hand.

SF: Any future projections on the industry?

TC: I see more consolidation in this industry. Fewer and fewer members are adapting to the future, and some of the new entrants don’t take the time to understand how the business works. They may not be traditional consolidators, but more activity with recyclers like us buying a smaller operator in a different area and bringing all the expertise that we have developed to that market. We are seeing that with our acquisition of Allen’s. They were a top player in Calgary, but you need a succession plan.

MW: The industry will keep growing and changing. As the world becomes more focused on the environment, recycling cars in an environmentally friendly way will play a big part in that. This will lead to better quality used auto parts and more efficient, environmentally responsible recycling processes. Also, with new parts becoming harder to get, auto recycling will become even more important for consumers. The industry is adopting new technologies and responding to the increased demand for sustainability. I believe this industry is as important as it has ever been.

AB: Costs keep increasing—especially labour—but also ballooning overhead. Meanwhile, prices have been stagnant. I’m not sure if most recognize it as a silver lining, if you act. If we do nothing, then we will all have reduced bottom lines.

Those who put a strong emphasis back on the metrics of their business; pay special attention to cycle times and their adjusted unit overhead as well as how that number is impacted, will undoubtedly prosper. Now more than ever we need to focus heavily on lean systems, added revenue streams and the broader concept of diversification. We have always pushed warranties, added product lines, put a strong emphasis on new parts, adopted a hybrid facility approach with a self-service yard, and, even with no insurance contracts, have maintained a healthy rebuilder business.

SF: Any final thoughts you would like to share?

AB: COVID forced a lot of re-thinking, and many of the changes that were thrust on us, we have kept and embraced. Complacency is a negative force if you don’t counter the mindset of “we have always done it this way.” The collaboration I am seeing today is a good thing for the industry, and with the advent of EVs entering our business it is even more important that we share and learn from one another.

TC: I would like to figure out a way that we can have more trading beyond B.C., and now Alberta. I don’t know what the rest of Canada thinks of West Coast recyclers. I’d like to be able to do some more business with the places out East.

MW: Each day presents its challenges, but it’s a rewarding grind. I’m grateful to be part of such an innovative industry. What I love most about this industry is that, despite being competitors, we continually support one another.